Denim

Denim

ISKUR Group’s journey, since its foundation in 1990, is actually a summary of the history of Turkish industry. Founded in 2015, Iskur Denim is an important part of ISKUR Group’s textile investment. Featuring four open-end yarn operations, 1 Vortex yarn operation, and 2 ring operations,

ISKUR Group not only meets Iskur Denim’s need for yarn, but also serves as a yarn supplier for many companies in Turkey and abroad.

Owning such a great yarn source is such an important value for Iskur Denim’s quality and diversity of products.

Iskur Denim, which is a fully integrated facility, weaves indigo-dyed yarns at Iskur Group’s weaving facility and creates unique fabrics at exclusive finishing machines.

Another important difference that distinguishes Iskur Denim from its competitors is that the founder of the company Kadir Kurtul, reflects the importance he gives to the lands he was born and raised in his entire business life.

On the 2.5 million square meter-area, it still manufactures organic cotton and carries out organic agriculture.

This organic cotton turns into products at Iskur Group’s facilities. Moreover, it makes great investments in natural energy resources and provides sustainability not only in production but also in production resources, such as wind energy investment that generates 70 million kWh electricity and solar energy systems that generate 5.64 GWh electricity a year.

In the co-generation energy center In the co-generation energy center owned by Iskur Denim, both electricity and heat are produced with the same system, and thus, up to 1.000 tons of co2 emission per year is prevented with the savings provided. This is equal to co2 absorbed by 495,000 trees.

Founded in 2018, the Re-cycled yarn production facility summarizes Iskur’s policies regarding waste management. With a current production capacity of 50 tons/day, Re-Cycled yarn production facility processes all textile waste and turn it into new products.

The R&D center, founded in collaboration with a university, designs future technologies and processes for all facilities.

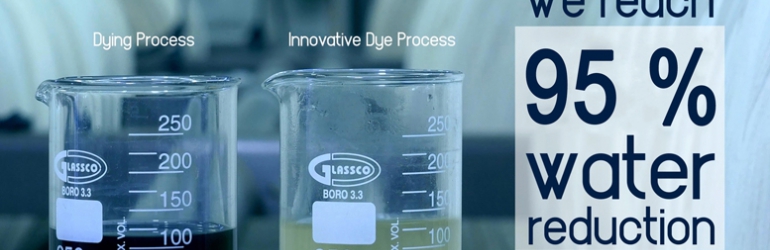

As a result, the center carried out a project under the motto “We Are Water (WAW)” to decrease the use of water in indigo dying down to 95 ‰, creating consistency with other sustainability projects.